The surface quality of a solar cell significantly influences its efficiency potential. We are therefore working on various methods and technologies for passivation and the optimization of light trapping in silicon solar cells in the "Coating Technologies and High-temperature Processes" Research Topic. The focal points of our work include

- Single and multilayer anti-reflective coatings

- Dopant precursors and multifunctional layers

- Passivation layers and layer systems

- Barrier layers

- Materials: among others: SiNx, SiOx, SiCx, Al2O3, a-Si (i/n/p), c-Si (i/n/p), ITO

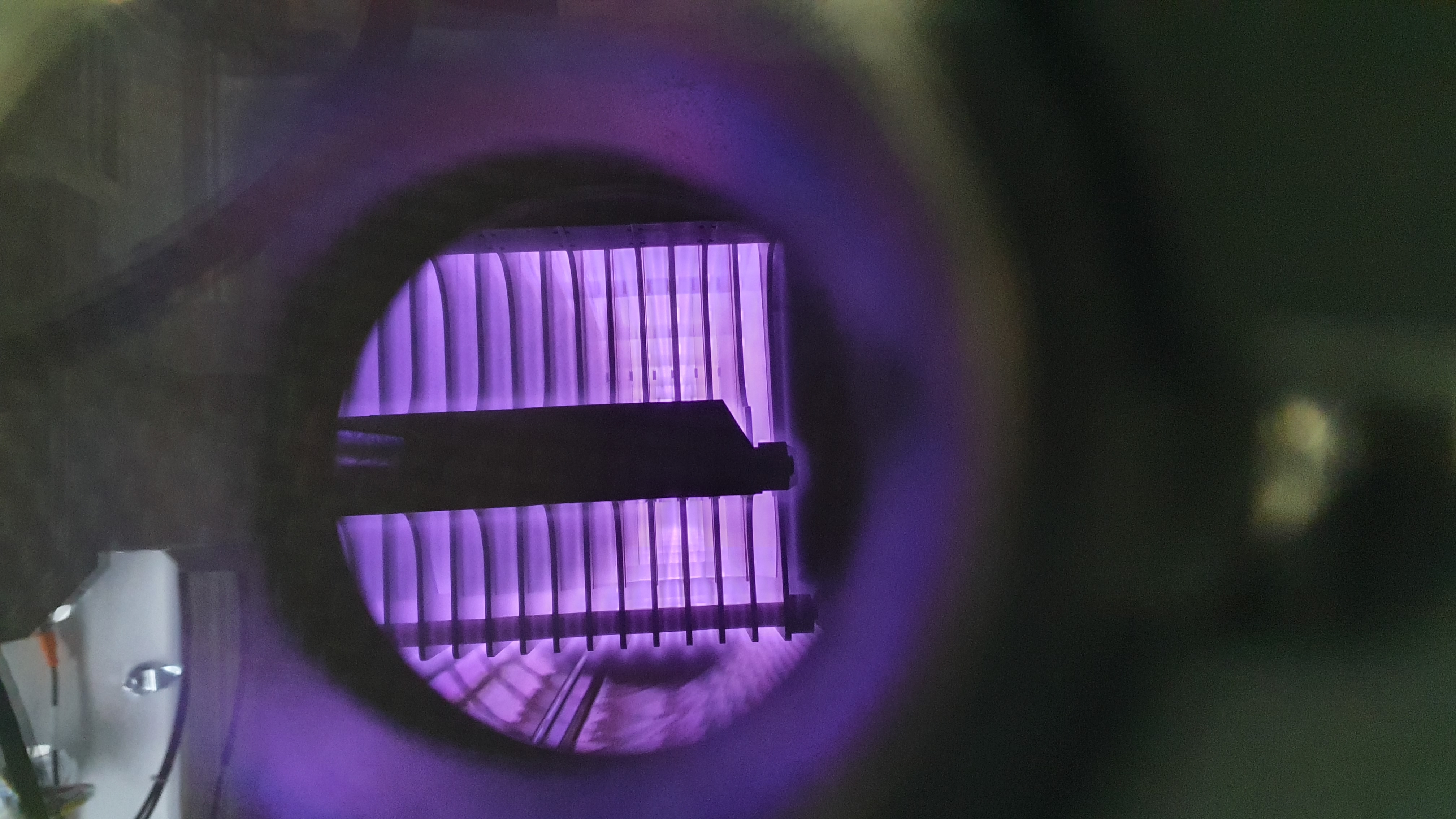

- Deposition technologies: PECVD, LPCVD, PVD, ALD

Solar cells require differently doped areas, e.g. the pn junction or »high-low junctions«, which fulfill different functions. In addition to the established method of tube diffusion used in photovoltaics, Fraunhofer ISE also has these other methods available for the realization of these full-surface or localized doping processes:

- Diffusion from dopants provided via the gas phase, currently POCl3 and BBr3 are available as sources at ISE

- Diffusion from deposited/printed and possibly structured layers in the tube furnace and in the continuous process

- Laser diffusion from deposited/printed layers and from the liquid phase, as well as laser transfer doping

- Thermal oxidation for post-treatment after doping processes, surface passivation and masking

The aim of our research work is to develop ideal and tailor-made solutions for the realization of passivated and doped areas for the large number of different solar cell concepts. The main requirement here is to create physically perfect surfaces and interfaces as well as doping (metal-semiconductor contact, minimization of recombination, structure size, etc.) and to use methods that are both cost-effective and can be implemented with the throughput required for production