The ramp-up of the hydrogen economy presents electrolyzer and component manufacturers, infrastructure operators and hydrogen producers with a wide range of questions regarding feasibility, cost efficiency, logistics, sustainability and, last but not least, implementation.

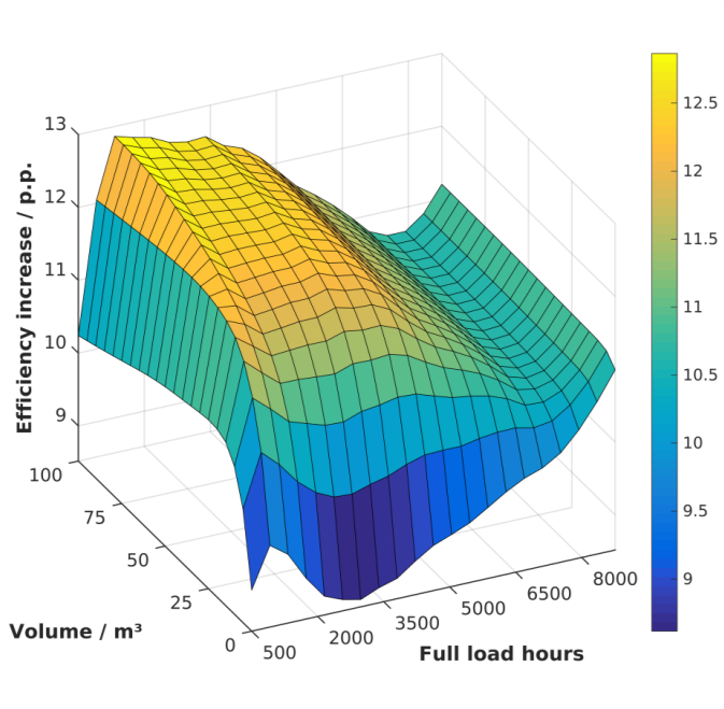

We prepare feasibility studies in which we evaluate and optimize electrolysis systems, hydrogen filling stations and other hydrogen-based infrastructure technologies (e.g. LOHC systems) in terms of their performance and cost-effectiveness for individual operating scenarios. In addition, we develop customized concepts for electrolysis systems and prepare market analyses. For system modeling, dynamic simulations and optimizations, we use our proprietary and powerful "H2ProSim" simulation software.

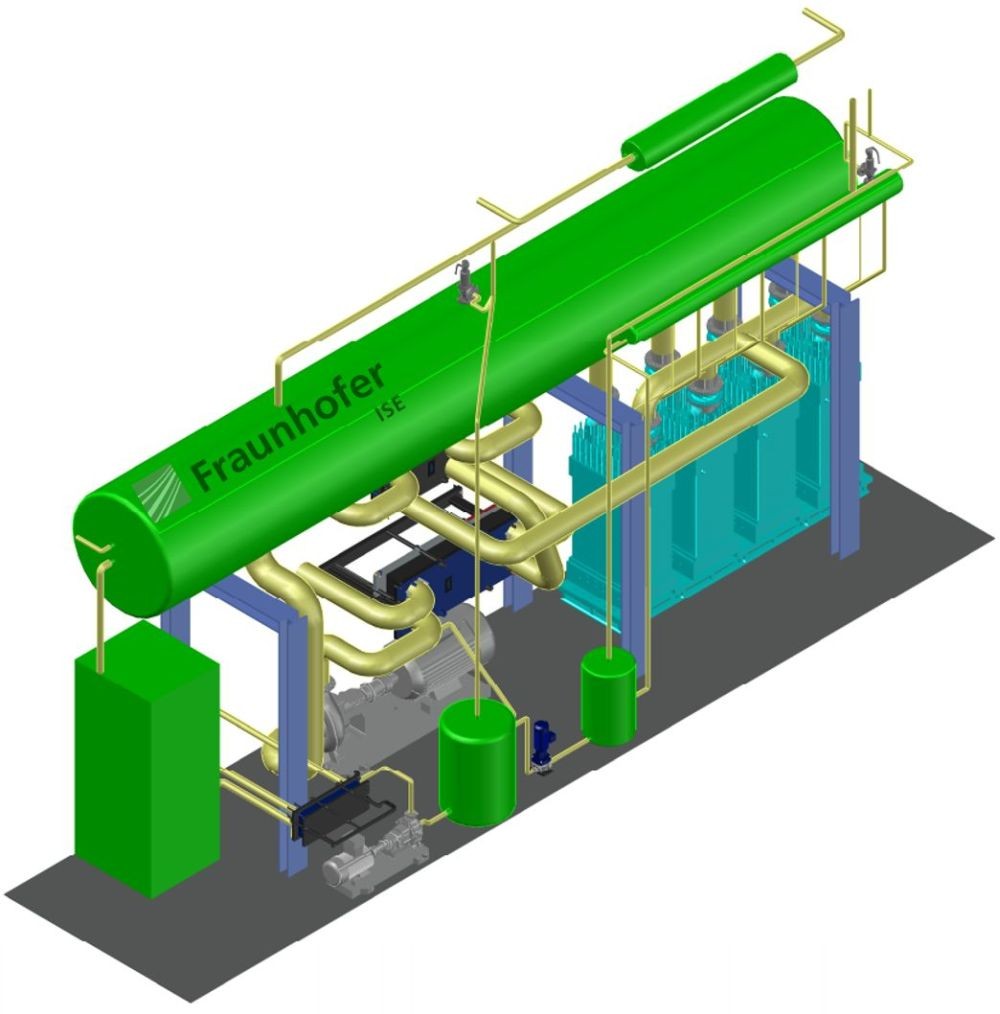

We complement our work with the monitoring of real electrolysis systems and hydrogen filling stations, both in practice and in the laboratory. This includes measurements for the condition-based maintenance of electrolysis stacks and component tests at our own hydrogen research filling station.