| Duration: | 06/2023 - 05/2026 |

| Contracting Authority/Sponsors: |

Federal Ministry of Economic Affairs and Climate Action (BMBK) |

| Project Partners: | PVA TePla Analytical Systems GmbH, Microvast GmbH |

| Project Focus: |

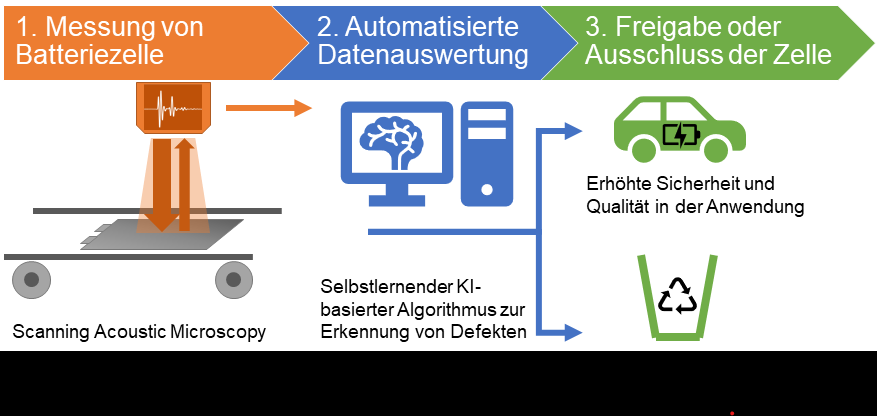

SAMBA – Scanning Acoustic Microscopy-based Battery Analysis

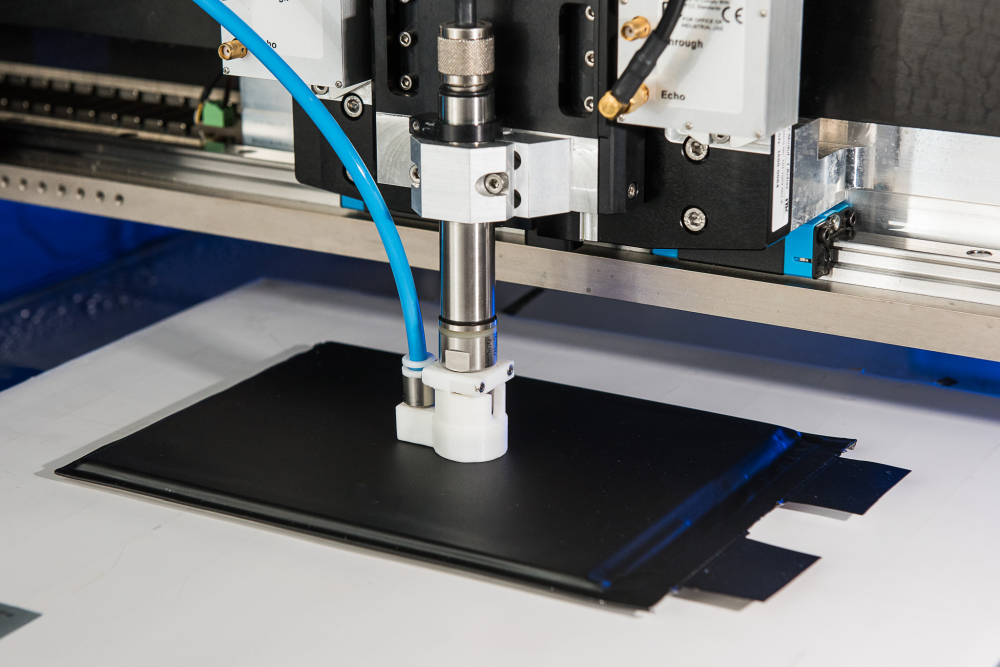

Inhomogeneities in battery cells have a negative impact on service life and jeopardize safe operation. Currently, there is a lack of suitable detection options in battery cell production to identify such defects reliably, quickly and cost-effectively. As part of the »SAMBA« research project, an ultrasound-based non-destructive testing method is being developed to inspect battery pouch cells for quality assurance purposes. Scanning Acoustic Microscopy (SAM) is used to generate image data that is subsequently analyzed by an automated AI-based evaluation routine. The goal of the project is to build a demonstrator for the random rapid analysis of pouch cells and test it in a real-world operational environment.

Quality defects at cell level such as gas inclusions or safety-relevant defects such as inclusions of foreign particles or defects in the separator have a negative impact on the service life of battery systems or, in the worst case, jeopardize their safe and reliable operation. This can lead to extensive recalls in the industry due to such defects. Improved quality control at the end of production, before battery cells are installed in modules or before further use in second-life applications, can sustainably improve the safety and consequently also the acceptance of the technology.

This is where the »SAMBA« project comes into play and is concerned in particular with the development and scientific validation of a novel, ultrasound-based measurement method for detecting inhomogeneities and defects in battery pouch cells. The non-destructive and cost-effective testing method is based on ultrasonic scanning acoustic microscopy (SAM) and allows spatially resolved detection and description of anomalies. Within the scope of this project, an offline solution with TRL 6 is initially targeted. Based on previous scientific preliminary work, the novel method for quality assurance will be scientifically validated and optimized. For this purpose, commercially available battery cells with specifically introduced defects will be characterized. The procedure is to be automated to a large extent. An implemented algorithm based on artificial intelligence (AI) with machine learning methods enables the identification, localization and categorization of defects in SAM image files. Post-mortem analyses are used to extensively characterize the cells afterwards and compare them with the results of the SAM experiments.

Furthermore, within the framework of this project, we are supporting our industrial partners PVA TePla Analytical Systems GmbH and Microvast GmbH in the development of a measuring stand that can be integrated into cell production and in the scientific evaluation of the process with regard to its suitability for quality control on an industrial scale.