| Duration: | 06/2023 - 05/2026 |

| Contracting Authority/ Sponsors: | Federal Ministry of Economic Affairs and Climate Action (BMWK), Projektträger Jülich (PtJ) (Förderkennzeichen 03EN4054A) |

| Project Partners: | MAHLE Behr GmbH & Co KG, Robert Bosch GmbH (associated Partner) |

| Project Focus: |

QUEEN-HP – MEGA: Microchannel Evaporators with Geometrical Adaptions

Quiet Efficient Electric Natural Refrigerant Heat Pumps

Heat pumps play a crucial role in the future climate-neutral heating and air conditioning of buildings. In 2021, heat pumps were used in half of all new buildings. Germany recorded the operation of 1.2 million heat pumps in the same year. The majority of these heat pumps (70%) use air as a source. As their numbers continue to rise sharply, an increasing challenge arises: reducing heat pump noise to a minimum. To meet this challenge, a project network of heat pump manufacturers, component suppliers and research institutes has joined forces to minimize the noise generated by air-to-water heat pumps.

In the technology project »Microchannel Evaporator with Geometric Adaptations«, microchannel evaporators of different designs are investigated for their performance and certain sector of the heat exchanger are optimized.

In the evaporator of a heat pump, thermal energy is extracted from the ambient air by flowing it - driven by a fan - through the evaporator. By deflecting the flow at the fins of the heat exchanger, the airflow generates noise that is to be reduced to a minimum. Noise increases as the air velocity increases, so the aim is to reduce the air velocity.

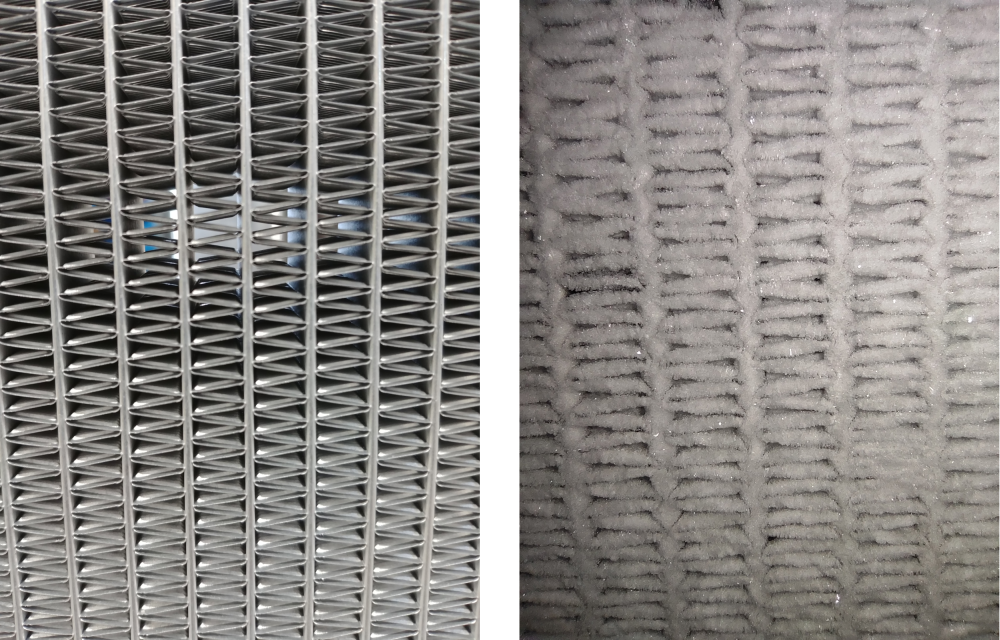

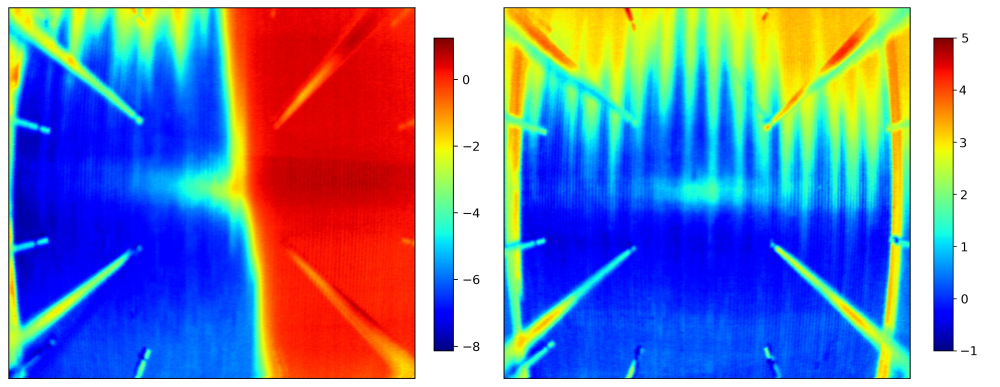

Microchannel evaporators, which are the focus of this technology project, have shown the problem in previous investigations compared to conventional round tube fin evaporators that they have a poorer refrigerant-side distribution to the parallel tubes in the evaporator and a faster blocking of the heat exchanger due to ice formation. Advantages of microchannel evaporators are a significantly lower CO2 footprint in production, better recyclability, lower refrigerant charge and very good heat transfer properties, making them very suitable for use in heat pumps.

In this project, the problem of rapid icing and defrosting with condensate drainage will be reduced by a special refrigerant-side flow routing, improved fin design and surface modification. Maldistribution is expected to be reduced by testing various designs for improved uniform distribution. In combination, evaporator blockage due to ice formation can be expected to decrease and the area available for heat removal from the air can be improved through optimized uniform distribution on the refrigerant side. Reduced required air volume contributes to reduced noise.