| Duration: | 04/2023 - 03/2026 |

| Contracting Authority/ Sponsors: | Federal Ministry of Economic Affairs and Climate Action(BMWK), Funding indicator: 16BZF361B |

| Project Partners: | Precitec Optronik GmbH Precitec GmbH & Co. KG |

| Project Focus: |

Quaze – Optical Test Method for Determining the Quality of Battery Cells

Development of a Self-Learning Process for Determining Quality in Battery Cell Production Based on Optical Thickness Measurement

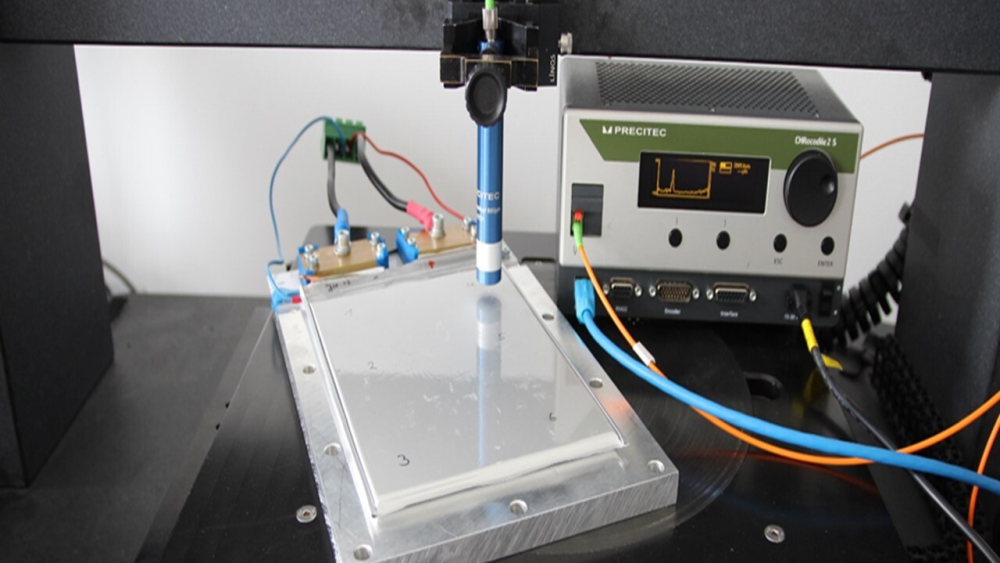

To reduce the high reject rates in battery cell production, early feedback on the quality of the cells from the production process is needed. In the Quaze project, together with our industrial partners, we are pursuing an innovative approach to non-destructive quality determination of battery cells using optical measurement technology that can be easily integrated into production processes.

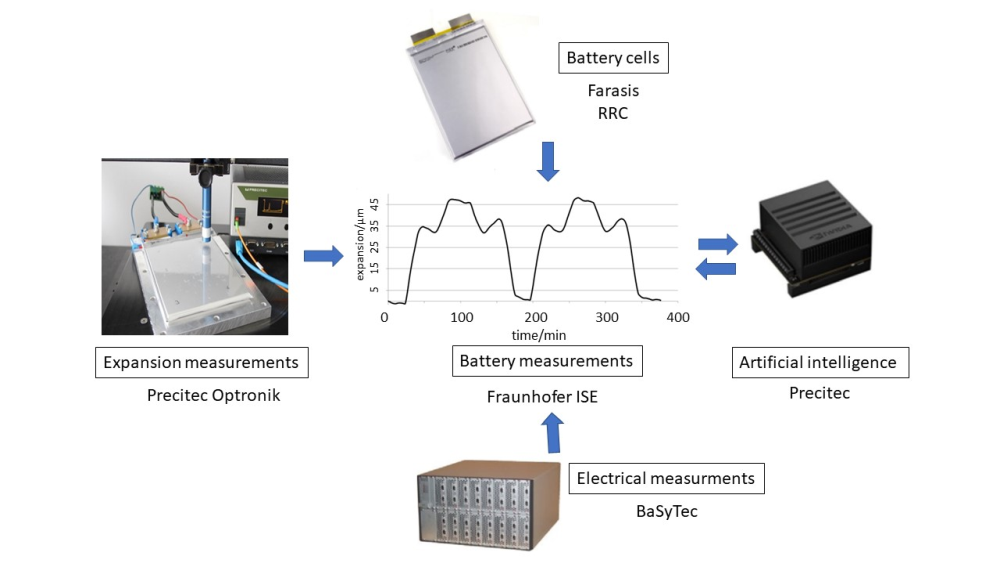

Due to the intercalation of lithium ions on the anode side, battery cells expand during charging and contract during discharging. This volume change of the battery cells is investigated in this project with regard to the expected behavior as well as indicators for quality defects.

The aim is to develop a solution for efficient quality determination, in particular for the implementation of optical sensor technology in industrial production facilities for the generation of extensive measurement data and their evaluation using artificial intelligence (AI).

Defects in battery cells can reduce service life and jeopardize safe operation. It is therefore important to detect quality defects as early as possible during production. Previous non-destructive methods detect critical defects only inadequately and often do not allow conclusions to be drawn about the location and cause.

The consortium of the joint project Quaze, consisting of the industrial partners Precitec Optronik GmbH, Precitec GmbH & Co. KG and Fraunhofer ISE as well as the associated partners Farasis Energy Europe GmbH, RRC power solutions GmbH, BaSyTec GmbH, aims to develop an innovative and non-destructive testing method for the precise measurement of local volume changes on battery cells during cycling and, derived from this, the identification of quality defects.

The aim is to detect battery defects as early as possible in the production process using a new testing method. The method is based on the spatially resolved detection of mechanical anomalies by means of optical distance measurements for battery cells and complements the electrical characterization that has been common up to now. This improves the quality and safety of battery cells. Early detection in production can significantly reduce scrap, saving costs and improving the environmental performance of battery technology. These test methods can be integrated into standard end-of-line testing and measure the reversible expansion of battery cells during their charge or discharge cycle. Untypical behavior in volume expansion attributable to quality defects can thus be identified at an early stage.

The integrated measurement of battery cell expansion can shorten the production ramp-up-phase and save valuable resources, particularly when introducing new product batches, suppliers, or changing/ interrupting production steps.

In the project, numerous commercial pouch and cylindrical battery cells are examined during cyclization. Very large amounts of measurement data are generated in the process. These are used to generate models with machine learning methods - in particular deep learning methods - which provide predictions about the quality defects and the expected aging development. These methods, in combination with precise point measurements, enable a significant improvement of previous quality determinations and lifetime predictions. For the development of a lifetime prediction algorithm, the irreversible expansions of battery cells are measured during specific battery cycles.

From these innovative AI-supported measurement methods, important new insights into the relationship between defects and the volume change of battery cells will emerge that go significantly beyond the current state of knowledge. The support of the consortium by industrial partners from battery manufacturing accelerates the transfer of results.