| Duration: | 05/2019 - 10/2022 |

| Contracting Authority/ Sponsors: |

Federal Ministry of Economic Affairs and Climate Action (BMWK) |

| Project Partners: | ISRA VISION GmbH |

| Website: | Enargus Förderprojekte |

| Project Focus: |

NextTec – Contactless Performance Measurement for Solar Cells

Next Generation PV Production Technologies for Increased Throughput

To mitigate threatening supply bottlenecks and reduce the manufacturing costs of silicon solar cells, a high production throughput is necessary - a decisive factor not only for PV expansion in Germany, but worldwide. A consortium led by Fraunhofer ISE has therefore developed a proof-of-concept for a future production line with a throughput of 15 000 to 20 000 wafers per hour as part of the "NextTec" project funded by the German Federal Ministry of Economics and Climate Action (BMWK). This corresponds to at least a doubling of the throughput compared to currently used production systems. One focus of the work at Fraunhofer ISE has been the accelerated measurement of the current-voltage characteristic.

In order to increase the throughput of the current-voltage characteristic (IV characteristic) measurement - the most important characterization method in manufacturing - we have developed a novel method in cooperation with the University of New South Wales (Australia): It enables contactless measurement on the moving solar cell. The elimination of time-critical and mechanically stressful contacting proves to be particularly advantageous for multi-busbar solar cells, whose contacting is cost-intensive and leads to a reduction in illumination homogeneity.

The method, for which Fraunhofer ISE has filed a patent application, is based on the following four pillars:

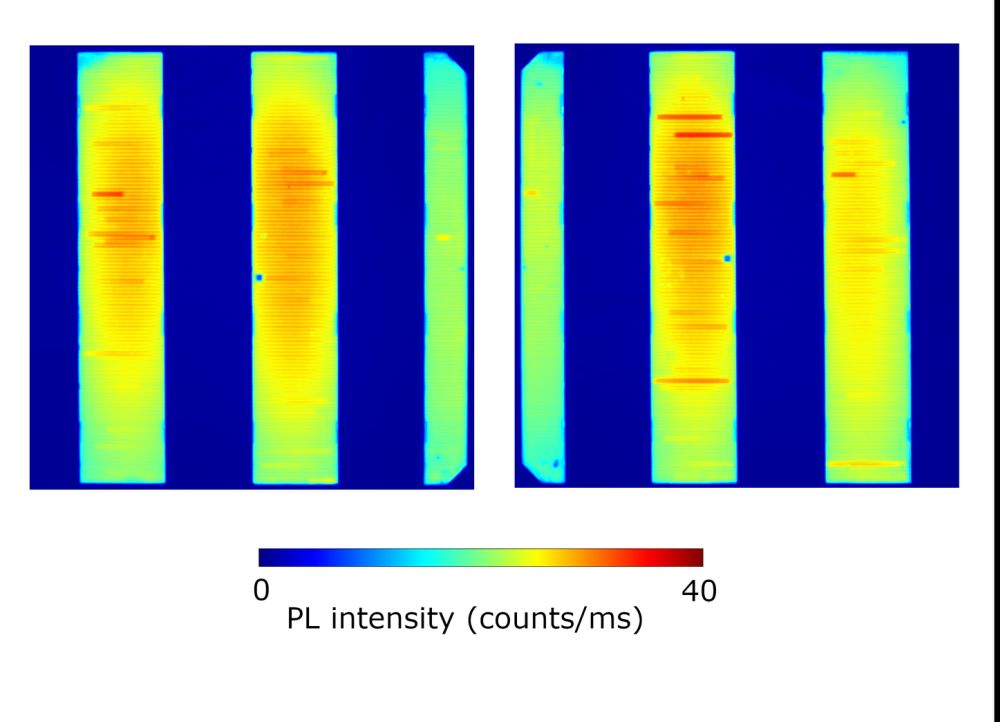

- Photoluminescence measurements with varied excitation intensity to determine the pseudo-IV characteristic curve.

- Contactless electroluminescence excitation spectroscopy to determine the relative quantum efficiency

- Spectroscopic reflectance measurements for scaling of relative to absolute quantum efficiency

- Photoluminescence measurements under partial shading of the cell to determine the internal series resistance of the solar cell (Fig.).

We have demonstrated the method for current solar cell types (PERC, TOPCon, SHJ) in the laboratory. We found good correlations between contacted and non-contacted data for all performance parameters of the investigated solar cells: The deviations between the contacted and non-contact measured current-voltage parameters (jsc, Voc, FF, pFF, η) are below 2.5 %rel, which is comparable to the typical absolute measurement uncertainty of calibrated test laboratories. We could show that the non-contact determination of current-voltage characteristics is possible. The time required for the measurement is limited only by the cell physics, not by the metrology.

The method has numerous advantages: In addition to the higher throughput, it treats the solar cells more gently, leads to fewer parts subject to wear and also allows additional measurement data to be gathered. We will demonstrate these advantages in future research and development collaborations and eventually develop them further on a prototype and product basis.