Press Release #2

Key Stakeholders in the PV Industry Call for Measures to Re-establish Upstream Solar Manufacturing Value Chain in Europe

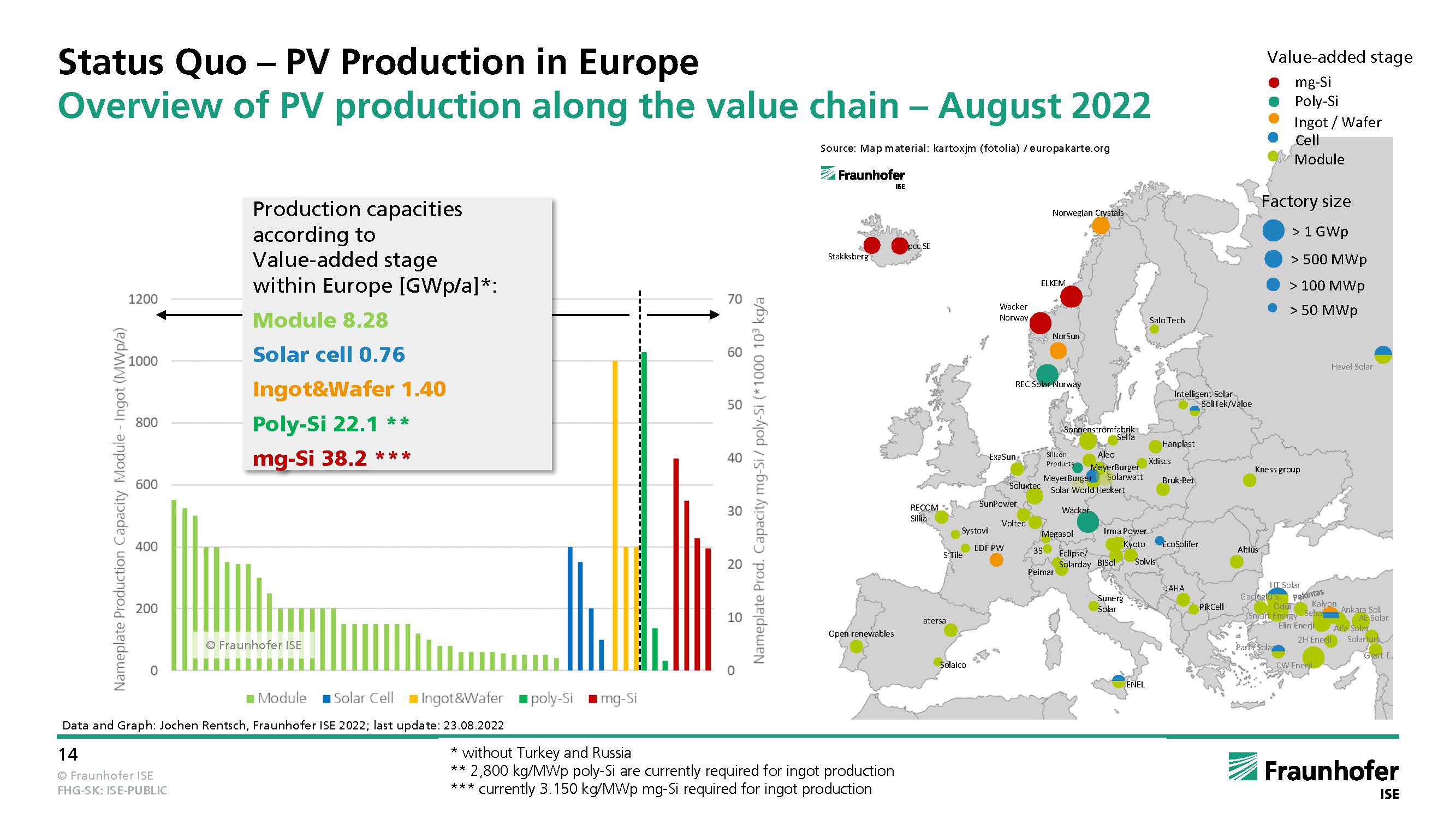

Most components and products within the photovoltaic supply chain are currently manufactured in China, which has more than 96 percent of the worldwide production capacity for silicon wafers, the core component of a solar cell. To reduce the large dependencies in the photovoltaic energy sector, a group of key stakeholders in the PV industry is calling on the political decision-makers to urgently adopt measures for a fair and level playing field in Europe so that they can act competitively in the PV upstream value chain.

Key representatives from the European PV community convened to discuss means for a timely buildup of a European PV upstream manufacturing value chain as well as the protection of the existing capacities. The players included polysilicon manufacturer WACKER, solar cell and module manufacturer Meyer Burger, silicon ingot and wafer manufacturers NorSun and Norwegian Crystals, the equipment manufacturer for silicon ingots and solar cells ECM Group as well as the research institutes Fraunhofer Institute for Solar Energy Systems ISE and Fraunhofer Center for Silicon Photovoltaics CSP.

The critical materials and products in the upstream value chain are silicon, silicon crystals and silicon wafers, as prerequisites for the manufacturing of solar cells, solar modules, and ultimately of solar power plants. The dependency on PV products from a single country would jeopardize the deployment of solar energy in Europe in case of potential supply disruptions. In a joint statement, the stakeholders call for immediate actions that enable the creation of a local, sustainable solar manufacturing value chain.

Effective measures could include subsidies for investments, a guaranteed and competitive electricity price and benefits for low CO2 emissions in product manufacturing. The overall aim is to generate a fair level playing field for the industry and thus to provide a fair competition.

“We are convinced that a sustainable European PV manufacturing industry can be revitalized with governmental support to promote the installation and operation of PV manufacturing facilities”, says Prof. Dr. Andreas Bett, director of the Fraunhofer ISE. “This would resolve Europe’s severe energy dependence significantly, while increasing economic value and creating jobs.”

“We need the right policy framework and more financial support mechanisms for making investments into PV value chain more attractive in Europe, especially for Capex and energy-intensive upstream manufacturing such as ingot and wafer production.”, says Carsten Rohr, Chief Commercial Officer at NorSun. “We should for example be able to benefit from sustainable production, both in terms of high environmental standards – including low carbon footprint – and social standards.”

“A temporary industrial policy to specifically promote the renaissance of a manufacturing industry for renewable energies is strategically wise and urgently needed. Industries based in Europe help securing the affordable energy supply of the future and also pay taxes here - if they are set up elsewhere, Europe will miss out twice in the end”, says Gunter Erfurt, CEO Meyer Burger Technology AG. “Moreover, the energy sector, as the basis of economic prosperity, is always of national security interest and renewables and especially their industrial and resilient local manufacturing need a new industrial policy focus against the backdrop of ongoing multiple global crises.”

Downloads

Last modified: